News

The main boiler loaded on LNG carriers is an important equipment that supplies steam to turbines for propulsion.

While boilers made by Mitsubishi Heavy Industries Marine Machinery & Equipment are highly reliable, depends on the water quality management in the boiler, layers of scales (hard, grayish, chalky deposits) may form on the inside of the boilers (on the water-side heat transfer surface).

Due to their low thermal conductivity, scales can cause the thermal efficiency of boilers to drop, resulting in energy loss and decreased durability.

Moreover, overheating resulting from heat transfer inhibition can cause damage to appear on the heat transfer surface and, in some cases, holes to form on heat transfer tubes, resulting in leaks.

Given that, we propose the chemical cleaning of the inside of boilers (the water-side heat transfer surface) to remove the layers of scales that have accumulated due to operation over time and return the heat transfer surface to its proper state.

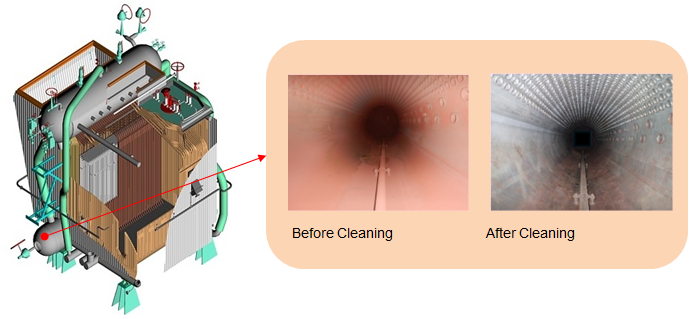

The inside of the heat transfer surface before and after chemical cleaning is as shown in the photos below (Photo of the water drum are shown as an example).

Performing chemical cleaning results in the removal of layers of scale that have accumulated over time and the restoration of heat transfer surfaces to a clean state.

The cleaning method we propose involves a neutral, ambient temperature chemical cleaning method that does more than other chemical cleaning methods to remove scales while keeping the base material itself from dissolving.

For boilers that have been in operation for a certain period of time, we encourage you to consider performing chemical cleaning to reduce the possibility of leaks occurring in the future.

Please submit any inquiries to [email protected].