PAUT TECHNOLOGY

WHAT PAUT IS AND HOW MCO-I UTILIZES IT

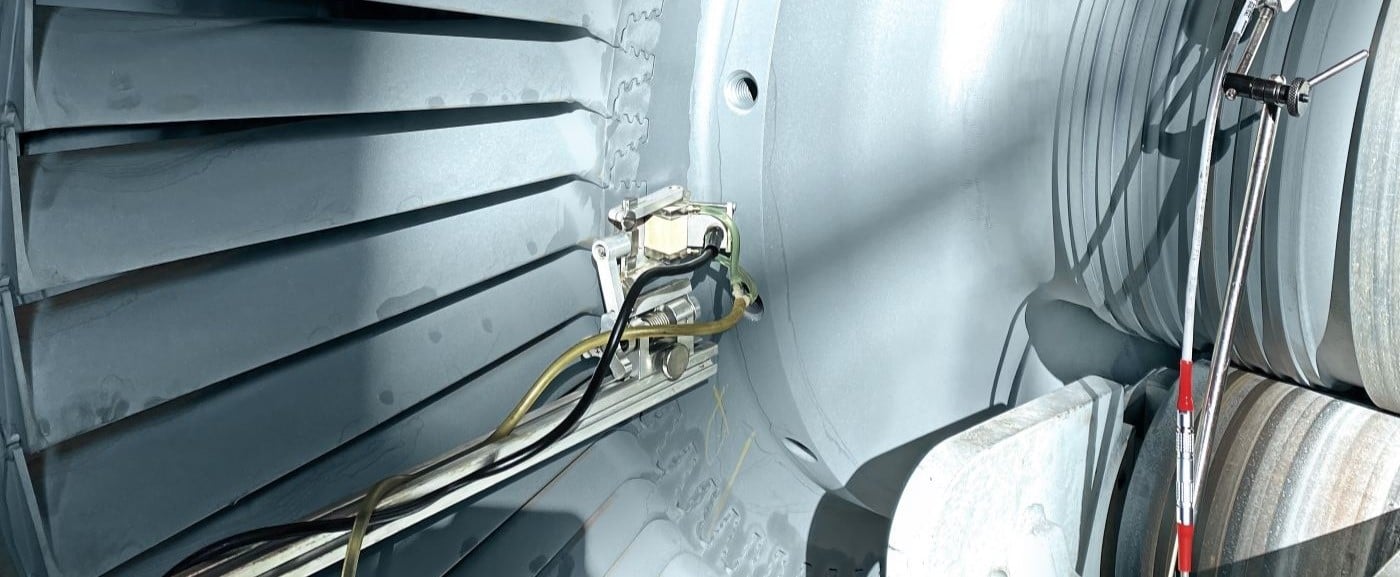

Mitsubishi Heavy Industries Compressor International Corporation (MCO-I) is utilizing Phased Array Ultrasonic Testing (PAUT) to bring more value to the end user through advanced steam turbine inspection. PAUT uses multiple ultrasonic elements and advanced signal processing to provide insight on the condition of steam turbine blade attachment areas, that could be invisible using other techniques. PAUT is a non-destructive testing technique, useful for investigating bladed rotor disks allowing for accurate sizing and mapping of rotor material defects.

PAUT is a very capable rotor diagnostic tool. To fully capitalize on its potential, we select the proper scanning equipment and plan the testing arrangement. Prior to inspection, we require dimensional details of the rotor and information about its service conditions and history.

PAUT BENEFITS

There are many benefits to utilizing PAUT for steam turbine maintenance:

- Scans with high accuracy to identify small anomalies

- Detects corrosion pitting and early stages of stress corrosion crack indications

- Store parts in an organized manner inside rugged, industrial boxes

- Allows end user to plan rotor maintenance and repair tasks to ensure steam turbine reliability

- Provides inputs for a detailed remaining life assessment analysis of the turbine rotor attachments

- Reduces risk of unplanned outages

- Minimizes downtime costs