REPAIR & REFURBISHMENT

PROVIDING RAPID, TURNKEY SOLUTIONS EVERY DAY

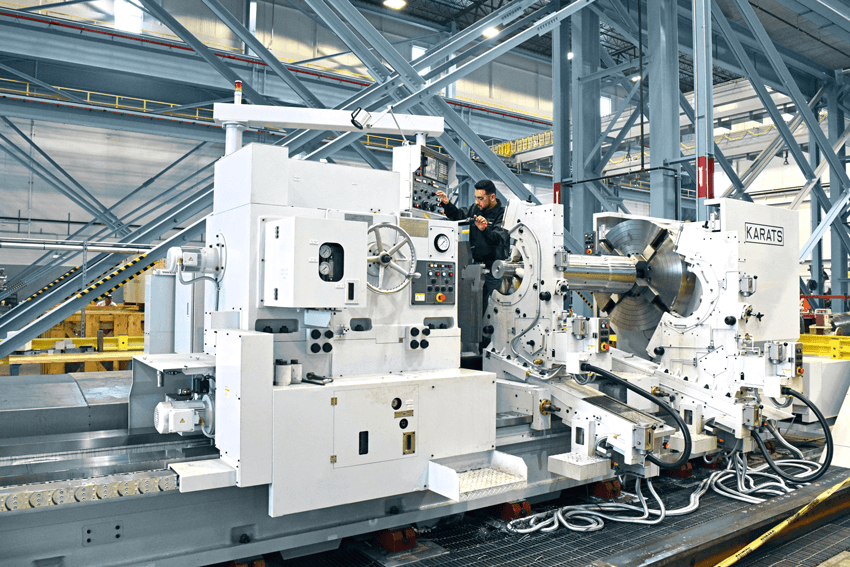

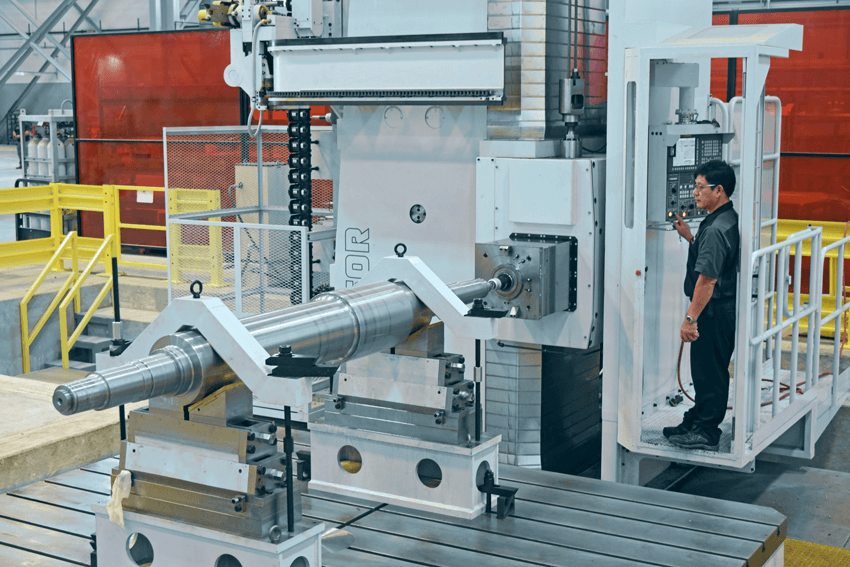

Whether you need routine or unexpected maintenance or repair, MCO-I provides rapid, turnkey solutions to minimize downtime and keep revenues flowing. Our state-of-the art service center, Pearland Works, features new, world class tooling capable of servicing Mitsubishi and other OEM rotating equipment. With best-in-class automatic welding systems, complete CNC capabilities, and high-speed balancing, we repair your machinery to the highest industry standards for reliability and accuracy.

THE +M DIFFERENCE

Mitsubishi Heavy Industries is a recognized industry leader in advanced technology. Our +M approach to service means we employ our proven designs within the existing envelope — injecting our Mitsubishi technology into any manufacturer’s equipment for upgrades and problem solution.

EQUIPMENT SERVICED

- Mitsubishi portfolio products and other OEMs

- Steam turbines

- Centrifugal, axial and integrally geared compressors

- Gear boxes

- Trip throttle and governing valves

REPAIR SERVICE

PHASE I AND II INSPECTIONS

- Visual and dimensional inspections

- Non-destructing testing (NDT)

- Phased Array Ultrasonic Testing (PAUT)

- High speed balancing

- Low speed balancing

GENERAL ROTOR REPAIRS

- Journal coating and/or grinding

- Trim part replacement

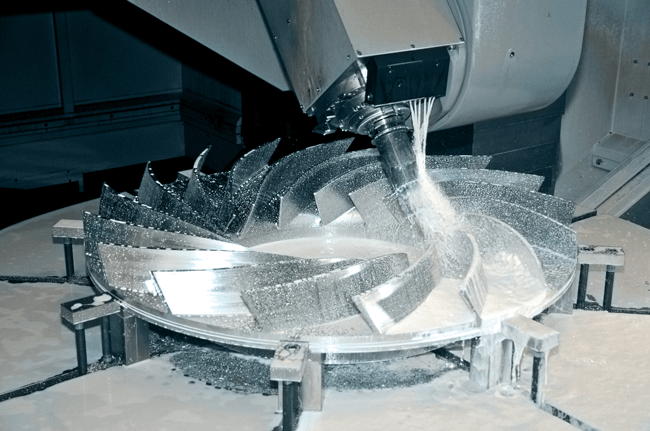

- Blade/impeller replacement

- Impeller over speed test up to 20,000 rpm

ADVANCED ROTOR REPAIRS

- Milling of axial entry blade roots

- Axial entry blade slot CNC machining

- Machine Upgrades

- Rotor restoration and redesign

- Complete overhaul

- ST blade conversions

ADVANCED WELDING CAPABILITIES

- Gas Tungsten Arc Welding (GTAW)

- Submerged Arc Welding (SAW)

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW)

READ MORE ABOUT OUR SUCCESSES

A case study on how a first generation syngas steam turbine was modified after catastrophic damage.