Examples of CO₂ Capture Initiatives From a variety of Flue Gas Sources

As a leader in CO₂ capture technologies, MHI provides solutions around the world. We are engaged in initiatives to capture CO₂ from a wide range of sources (see below).

Supplying plant to Petra Nova Carbon Capture (USA), the World’s Largest Post Combustion CO₂ Capture Project

MHI has supplied a CO₂ capture system to the Petra Nova Carbon Capture Project, the largest post combustion CO₂ capture project in the world that targets coal combustion flue gas. It is located in the southern part of Houston, Texas, USA, and commenced commercial operation at the end of December 2016.

This is a large-scale enhanced oil recovery (EOR) project conducted by Petra Nova Parish Holdings LLC, a subsidiary of JX Nippon Oil & Gas Exploration Corporation.

The CO₂ capture plant consists of flue gas pre-treatment (desulfurization), CO₂ absorption and regeneration, CO₂ compression, and utilities. It captures 4,776 tons of CO₂ per day from a coal-fired power generation plant, which contains a high concentration of CO₂ in its flue gas, with a CO₂ capture rate(Note) of 90%.

(Note) CO₂ capture rate (%): The ratio of CO₂ captured by our CO₂ capture plants to the amount of CO₂ contained in combustion flue gas.

CO₂ Capture Systems at Cement Production Facilities: Pilot Capture System (Canada) and FEED Contract for the UK's First CO₂ Capture Plant

In 2023, MHI delivered and installed a small-sized CO₂ pilot capture system called CO₂MPACT™ for Heidelberg Materials, a major global cement manufacturer, at its cement plant in Edmonton, Alberta, Canada, and is conducting a demonstration test for CO₂ capture.

Also in 2024, MHI is being deployed by Heidelberg Materials UK, for Front End Engineering Design (FEED), to further study the specifications of a CO₂ capture plant at its Padeswood Cement Works in Flintshire, UK.

This project is a partnership between MHI and Worley, a global industrial engineering company of energy, chemicals and resources experts, and will implement the basic design of the CO₂ capture plant using the Advanced KM CDR Process™, our proprietary CO₂ capture technology developed jointly with the Kansai Electric Power Co., Inc.

Through these projects, we are supporting Heidelberg Materials' vision of leading the decarbonization of the cement industry and promoting the establishment of a CCUS value chain.

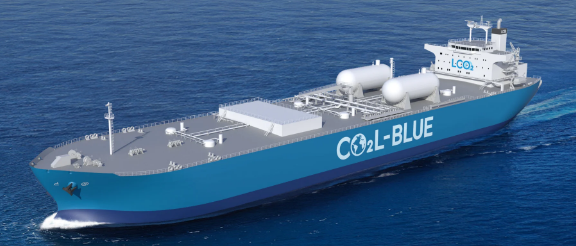

Mitsubishi Shipbuilding Holds Christening and Handover Ceremony in Shimonoseki for Demonstration Test Ship for Liquefied CO₂ Transport -- New Vessel "EXCOOL" to Contribute to Protecting the Global Environment --

Mitsubishi Shipbuilding Co., Ltd., MHI Group company based in Yokohama, held a christening and handover ceremony for a demonstration test ship to transport liquefied carbon dioxide (LCO₂) in 2023. The ship will be used for the CCUS R&D and Demonstration Related Project / Large-scale CCUS Demonstration in Tomakomai / Demonstration Project on CO₂ Transportation (the demonstration projects) being conducted by Japan's New Energy and Industrial Technology Development Organization (NEDO). The ceremony took place at the Enoura Plant of MHI's Shimonoseki Shipyard & Machinery Works in Yamaguchi Prefecture, in the presence of the ship owner Sanyu Kisen Co., Ltd. and other related parties.

CCUS (Carbon dioxide Capture, Utilization and Storage) is gaining attention as an effective means of achieving a carbon-neutral society. Because the sources of CO₂ emissions are often located distant from the sites selected for carbon utilization or storage, demand is expected to increase for LCO₂ carriers being able to transport such cargo safely and economically. MHI Group utilized its expertise and advanced gas handling technologies cultivated through the construction of liquefied gas carriers (both LPG and LNG types) to handle the entire design and construction of the vessel, including the cargo containment system.

Related Information

Related Products & Solutions

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- MHI Awarded a Study on CO₂ Capture Modules for Floating Production Storage and Offloading vessels (FPSOs)

- Mitsubishi Shipbuilding Acquired Approval in Principle (AiP) for the Basic Design of an Onboard Carbon Capture and Storage System

- Osaka Gas and MHI Launch CO₂NNEX® Digital Platform for Management/Transfer of Clean Gas Certificates for e-Methane, for Use during Expo 2025

- Approval in Principle (AiP) Acquired for Low-Pressure Type Coastal Liquefied CO₂ Carrier, Towards Realization of Domestic CCS Business

- Launch of Demonstration Test for CO₂ Capture from Chemical Recovery Boilers at Paper Mills in Japan, Contributing to the Decarbonization of the Pulp and Paper Industry

- Europe's First Post-Combustion Carbon Capture Plant Starts Operation with MHI Technology as part of the Ravenna CCS Project, Phase 1

- World-first Trial of New Technology to Recycle CO₂ Emissions from Steel Production Begins at ArcelorMittal Gent, Belgium

- MHI Selected as Technology Licensor for EET Industrial Carbon Capture Targeting UK's First Low Carbon Refinery