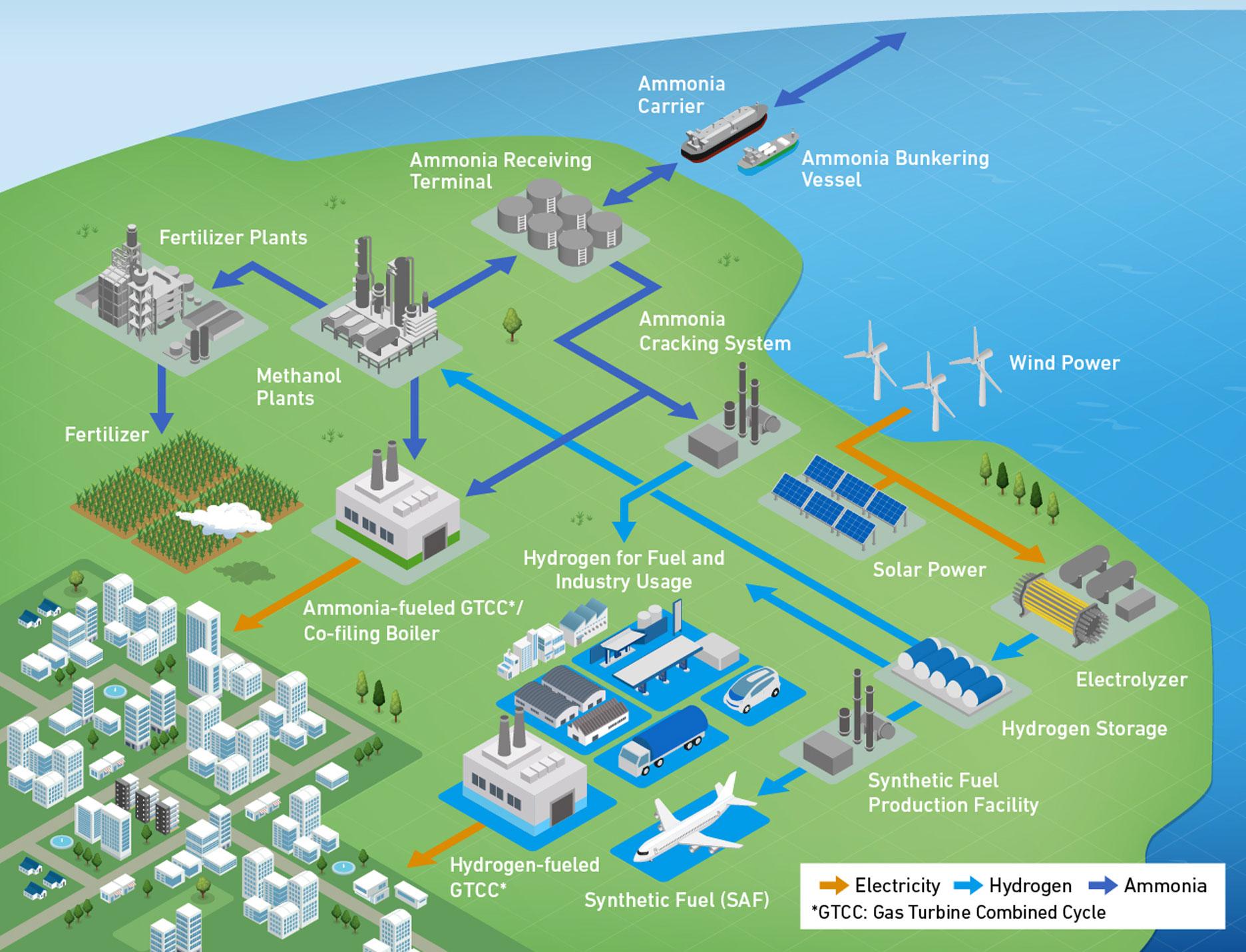

Hydrogen and Ammonia Value Chains MHI Group Envisions

There are many challenges in expanding hydrogen and ammonia value chains. For example, how to produce hydrogen and how to utilize it. Whether to directly use it or convert it to synthetic fuels. How to transport hydrogen easily and safely. Moreover, how to establish a value chain that encompasses production, transportation and utilization.

MHI Group is aiming to provide solutions to address those challenges.

We are developing innovative technologies and products, such as water eletrolyzers which produce hydrogen using electricity generated by wind turbines or solar panels; gas turbines which can directly utilize hydrogen or ammonia as fuels; systems for producing synthetic fuels converted from hydrogen; ammonia carriers with systems for safe handling and transportation after converting hydrogen to ammonia. These are some key components comprising a value chain.

Furthermore, building value chains that connect those key technologies and products are vital so as to accelerate the utilization of hydrogen and ammonia as realistic initiatives.

We will combine the technologies and products organically by cooperating with various partners and establish comprehensive value chains, contributing to the realization of a carbon neutral society.

Developing Hydrogen-fired Gas Turbines Towards Realization of Hydrogen Solutions Ecosystem

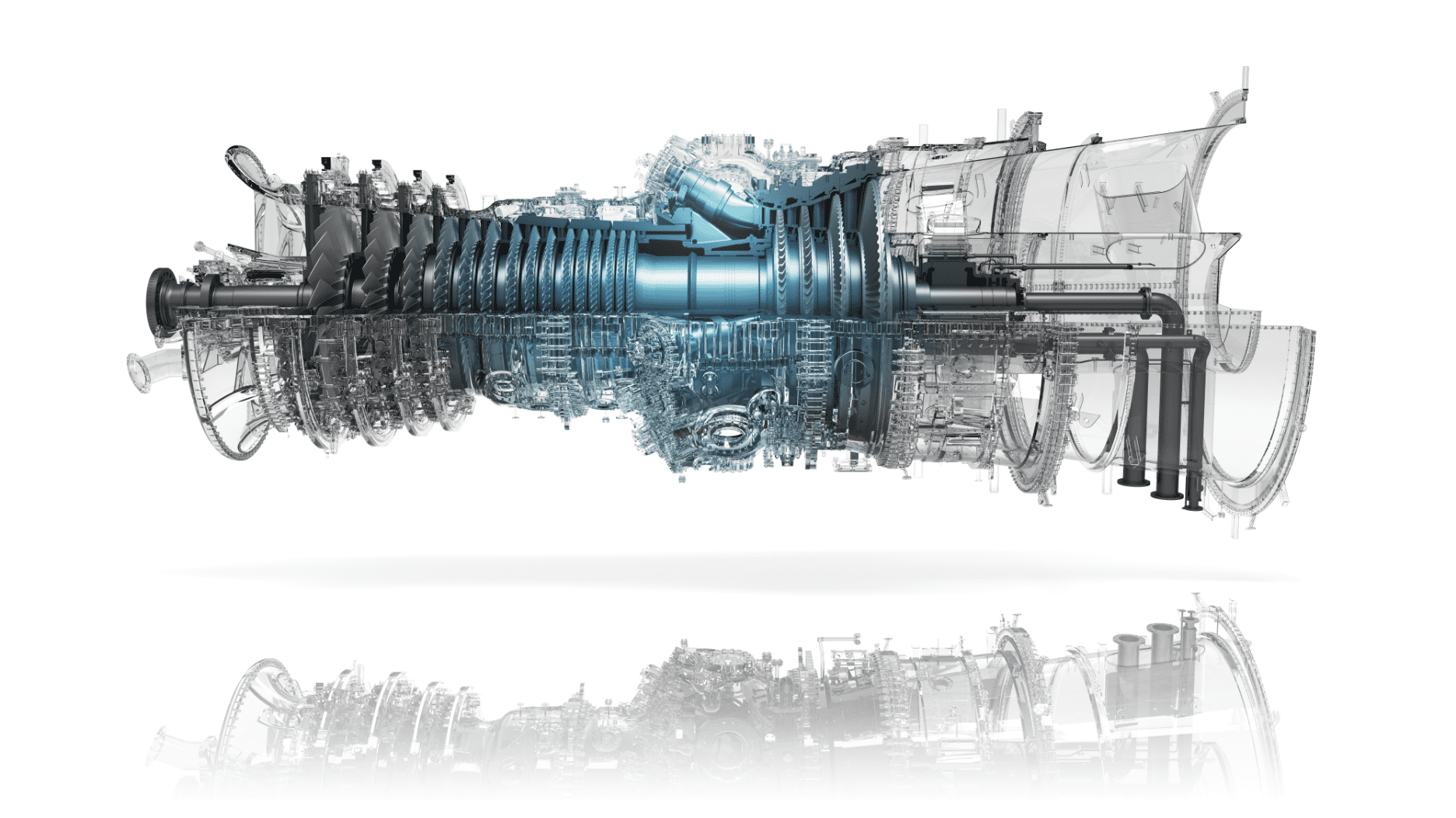

For the value chain that encompasses all aspects from hydrogen production to transportation, storage, and utilization, it is anticipated that large-capacity, high-efficiency hydrogen-fired gas turbines will help enable a smooth transition to a carbon neutral society by converting existing gas turbine facilities to low-carbon or decarbonized facilities with minimal modification, without needing large-scale renovations.

Since the 1970s, MHI Group has developed gas turbines that can be fueled by off-gas containing hydrogen, responding to customers’ needs for a method to effectively utilize off-gas from refineries, steel plants and other facilities. Leveraging our experience of developing and operating combustors for these industrial applications MHI is now working on developing next-generation combustion technologies which will make 100% hydrogen firing possible by resolving technical issues, such as hydrogen’s especially high combustion rate.

For the large frame gas turbine combustor, we have completed development of a combustor enabling 30% hydrogen co-firing, and in 2022, we successfully conducted a combustion test with a 50% hydrogen mix. Following this successful test of the combustor, in November 2023 we demonstrated a successful operation of 30% hydrogen co-firing at our Takasago Machinery Works' gas turbine combined cycle (GTCC) power generation validation facility using our state-of-the-art 1,650℃ class J-series Air-Cooled (JAC) gas turbine. We are now preparing for demonstration operation of 50% hydrogen co-firing at this facility, and will further continue development aiming commercialization of 100% hydrogen firing gas turbines using a new combustor after 2030.

Another valid approach to decarbonization is utilizing ammonia, which acts as a hydrogen carrier and is easier to handle than hydrogen on its own. The use of ammonia helps stabilize energy supplies and address environmental issues, thus facilitating a smooth Energy Transition. MHI has also begun work on the development of a 40 MW-class gas turbine that directly uses 100% ammonia fuel. We are pursuing combustor development in the lead up to commercial unit operation and market launch in FY2025 or thereafter.

Related Information

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- MHI Starts a Study on Optimizing the Decarbonization Value Chain Using Green Hydrogen and Ammonia Exported from India - Initiative under METI's "The Global South Future-Oriented Co-Creation Program"

- Construction Begins on Hydrogen-Based Ironmaking Plant in Linz, Austria

- MHIET Launches 450kW Gas Cogeneration System Capable of Hydrogen Co-Firing as Reliability Verified through Demonstration Testing

- 50% hydrogen blend testing successfully completed at Georgia Power’s Plant McDonough-Atkinson in US

- Approval in Principle (AiP) for the Basic Design of a Large Ammonia-Fueled Ammonia Carrier Obtained

- MHI Successfully Achieves 1,200 Hour Milestone in Durability Test on Ultra-High-Pressure Liquid Hydrogen Booster Pump

- MHI Invests in Koloma, a US-Based Geologic Hydrogen Exploration Startup

- MHI and Taiwan Fertilizer Sign MoU for Joint Study on Developing Fuel Ammonia Value Chain in Taiwan