The Advanced Clean Energy Storage Project in U.S. for Power Generation Only with Green Hydrogen

The Advanced Clean Energy Storage Project in the U.S. aims to store hydrogen produced by water electrolysis (carbon-free "green hydrogen") using renewable energy, in underground salt dome caverns in Utah and to utilize the hydrogen to generate power.

MHI Group is working with Magnum Development, an affiliate of Chevron and the co-developer and operator of the salt dome caverns, to develop one of the world’s largest green hydrogen hubs using 100% renewable energy. The storage facility will use a 220 MW water electrolysis unit to produce up to 100 tons of hydrogen per day.

The hydrogen produced and stored here will be supplied to an 840 MW-class GTCC power plant (Intermountain Power Plant Renewal Project), which is being constructed by Intermountain Power Agency, a power generating cooperative in Utah, with MHI M501JAC gas turbines at its core. The plant will start operation in 2025 with a 30vol% hydrogen mixture and is expected to operate with 100% hydrogen by 2045.

Mitsubishi Shipbuilding Completesd Feasibility Study on Ammonia Supply Systems for Ammonia-Powered Maritime Solutions

Mitsubishi Shipbuilding Co., Ltd. (MHIMSB), a part of MHI Group, has recently completed a feasibility study in collaboration with U.S. startup Amogy on two ammonia solution concept designs: a carbon-free power train combining ammonia cracking and hydrogen fuel cell for ships and a hydrogen supply facility for supplying hydrogen as pilot fuel to ammonia fuel engines.

Amogy, a provider of mature, scalable, and efficient ammonia-to-power solutions, has developed an innovative ammonia-to-electrical power system that splits, or "cracks," liquid ammonia into its base elements of hydrogen and nitrogen, which then funnels the hydrogen into a fuel cell,generating high-performance power. In this feasibility study, MHIMSB and Amogy combined an onboard hydrogen production and utilization facility that utilizes Amogy's ammonia-cracking technology, with MHIMSB’s marine ammonia handling system MAmmoSS® (Mitsubishi Ammonia Supply and Safety System), to verify the feasibility of applying hydrogen extracted by ammonia-cracking technology to hydrogen fuel cells.

The two companies also verified the possibility of completely decarbonizing ammonia-fueled ships by converting the pilot oil required for ammonia fuel from conventional heavy oil and diesel to ammonia-cracked hydrogen.

Hydrogen Engine Generator Set Ready for In-house Evaluation

Mitsubishi Heavy Industries Engine & Turbocharger, Ltd. (MHIET), a part of MHI Group, has been working on commercialization of hydrogen combustion engines as a key product to support MHI Group's MISSION NET ZERO declaration that aims to achieve net zero emissions by 2040.

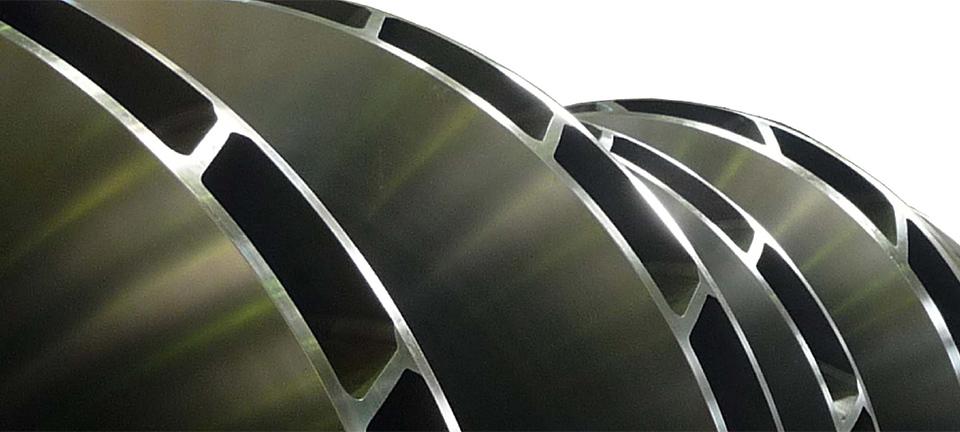

As the next step toward commercialization, construction of a 6-cylinder hydrogen engine generator set(Note) of 500kW-class output and of a hydrogen supply facility for supplying high-pressure hydrogen gas delivered on trailers to the generator set under reduced pressure has been completed. Starting with a trial run using natural gas, MHIET aims to confirm stable combustion at 100% load while running on hydrogen within this fiscal year.

(Note) A set of equipment required to generate electricity using a hydrogen engine, including a generator connected to the engine's output shaft, auxiliary equipment (piping systems for fuel gas, lubricating oil, cooling water, intake and exhaust gas, and a generator set control panel) required to operate the generator set, and an enclosure that houses and protects the generator and auxiliary equipment.

Related Information

Related Articles from Spectra - Our Online Magazine

Related Press Releases

- Approval in Principle (AiP) for the Basic Design of a Large Ammonia-Fueled Ammonia Carrier Obtained

- MHIET Achieves Rated Operation of a 6-Cylinder 500kW-class Hydrogen Engine Generator Set in Demonstration Tests

- MHI Successfully Achieves 1,200 Hour Milestone in Durability Test on Ultra-High-Pressure Liquid Hydrogen Booster Pump

- MHI Invests in Koloma, a US-Based Geologic Hydrogen Exploration Startup

- MHI and Taiwan Fertilizer Sign MoU for Joint Study on Developing Fuel Ammonia Value Chain in Taiwan

- Amogy and Mitsubishi Shipbuilding Have Completed a Feasibility Study of Ammonia Supply System for Ammonia-Powered Maritime Solution

- MHI and EGAT sign MoU to Introduce Hydrogen Large Gas Turbine Co-firing Technology in Thailand to Achieve Net Zero Goals