Advanced Flue Gas Treatment

Advanced Flue Gas Treatment

Emission control is one of the most important factors of Waste to Energy (WtE) plant.We have been working on this issue for a long time and have successfully developed a number of technologies in each element of the plant including incineration, flue, gas treatment, and ash treatment.

Base on MHIEC's (Mitsubishi Heavy Industries Environmental & Chemical Engineering Co., Ltd.,) accumulated technologies and know - how developed through long experiences, we can propose the advanced & environmental friendly flue gas treatment system.

Recycle of Usable Metals

| EURO 2000 Regulations | Mitsubishi WtE Plant A (288 t/day x 3 units) |

|

|---|---|---|

| Dioxins (ng-TEQ/Nm³) | 0.1 | 0.00011 |

| Dust (mg/Nm³) | 10 | 3 |

| HCl (mg/Nm³) | 10 | 2 |

| SOx (mg/Nm³) | 50 | 4 |

| NOx (mg/Nm³) | 200 | 110 |

Filtering reactor

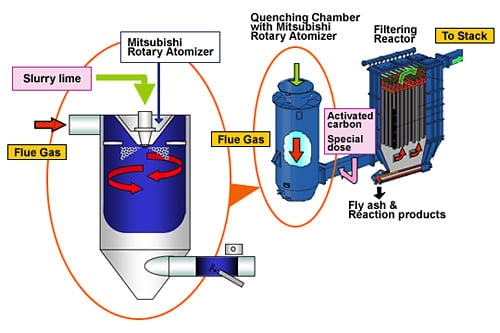

Dry system with filtering reactor

- High and stable performance for removal of HCl, SOx and Dust.

- No waste water treatment is required.

Semi-dry system with filtering reactor

- High and stable performance for removal of SOx and Dust, equivalent to Dry system with filtering reactor.

- Higher performance for removal of HCl, because slurry lime doing by Mitsubishi Rotary Atomizer.

- No waste water treatment is required.

Selective catalytic reactor

Dry selective catalytic reactor NOx removal system (SCR)

- Additional facility which can be installed after filtering reactor and achieve higher De-NOx performance.

- Less than 20 ppm of outlet NOx emission can be achieved.

- Low ammonia consumption, because of highly efficient catalytic reaction.

Hybrid Bag Filter

- In addition to the conventional functions of the filtering reactor (i.e. removal of HCl/ SOx/ Dust), Mitsubishi Hybrid Bag Filter can achieve high De-NOx performance.

- Mitsubishi Hybrid Bag Filter provides a total solution for emission control.

- Maintenance is easy because of its simple structure.