Newspaper Web Offset Press: LINEUP

DIAMONDSTAR

Defining the Next Generation of High-Speed Newspaper Offset Presses

In setting out to develop a new generation of newspaper presses, Mitsubishi sought to achieve several primary objectives towards the development of a press that would lower operational costs by promising ultra-high printing speed, quality, and productivity.

The Mitsubishi DIAMONDSTAR High-Speed Newspaper Offset Press is the product of these objectives.The DIAMONDSTAR provides a viable solution to today's demands for higher printing speeds and greater productivity by reaching an ultra-high production speed of 90,000 copies per hour.

Backed by the company's comprehensive technology, Mitsubishi and the DIAMONDSTAR will continue to deliver optimum solutions to meet the speed, quality and productivity challenges of future trends within the newspaper publishing industry.

The Mitsubishi DIAMONDSTAR is establishing newspaper standards today and defining productivity and quality standards for tomorrow.

Feature

High Productivity

Maximizing the advantages of high-speed operations while reducing makeready and startup waste

A higher rate of productivity is not necessarily realized simply by increasing the print run speed. To achieve greater productivity, efficient means of shortening press makeready time and reducing the quantity of start-up waste must be considered. High productivity on the DIAMONDSTAR high-speed press is achieved and maintained through the introduction of advanced equipment and functions developed specifically to reduce makeready time and paper waste.

- Narrow Gap Plate Cylinders

- By further narrowing the gap of plate cylinders, shock vibration has been significantly reduced, allowing the press to operate at higher printing speeds.

The narrower gap also contributes to quieter press operations.

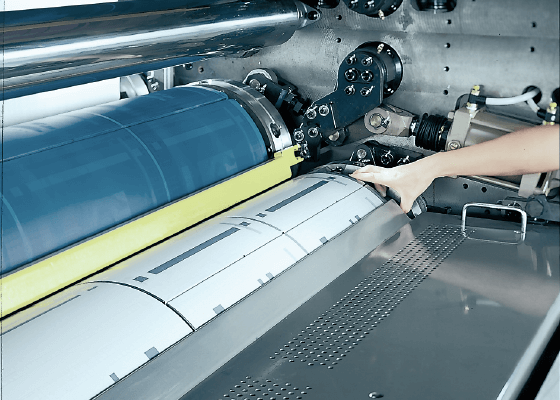

- Tool-Free Plate Lockup

- This newly developed technique facilitates the precision mounting and removal of printing plates.

Plate-changing operations are performed quickly and efficiently without the need of special tools.

- Automatic Rail-Type Web Threading

- Automatic Rail-Type Web Threading Quicker web-ups are now realized through use of a faster rail-type web threading system that significantly contributes to quicker press makeready.

- Independently Adjustable Three-Arm Reel Stand

- The heavy-duty reel stand can simultaneously accommodate three rolls of different web widths. This provides a shorter makeready for the next run when a different size web is required. Two-arm reel stands are also optionally available.

High Reliability

Optimizing the proven reliability of the shaftless drive system for extremely stable, high-speed press operations

Precise web tension control is a significant factor in achieving productive, high-speed runs. Mitsubishi's comprehensive engineering technologies, combined with the benefits of the shaftless drive system, provide the basis for realizing and maintaining an outstandingly high degree of web tension control throughout the entire production run. Structural enhancements, vibration reduction, and other reliability factors have all been thoroughly analyzed, reviewed and implemented.

- Shaftless Drive

- Mitsubishi shaftless drive technology is highly rated for its exceptional reliability proven both in Japan and overseas.

- Low Friction-Type Bearings

- Smooth and reliable operations at high printing speeds are realized through use of low friction-type cylinder bearings throughout the press.

- High-Rigidity Unit Frames

- Stable operations during high-speed press runs are also achieved as a result of highly rigid box-type unit frame construction.

This produces an integrated, rigid press structure with longitudinal and lateral press line stability.

- Flying Paster

- The flying paster suppresses web tension variations during high-speed roll splicing operations and minimizes paper waste.

High Quality

Advancing high-quality printing by enhancing established press features and functions

Increasing the running speed of the press leads to a number of new challenges, including the means for consistently maintaining high-quality printing. Through the development and implementation of new technologies and the improvement of existing technologies, Mitsubishi has actively met the printing quality challenge. Advancements in this area include the introduction of three ink form rollers and three dampening rollers, with additional improvement of register accuracy and folder precision.

- Three Ink Form Rollers with Three Dampening Rollers

- Each printing couple is equipped with three ink form rollers to ensure consistent ink transfer to the plate surface during high-speed operations. Complementing each ink train are three dampening rollers designed to apply an even film of dampening solution and contribute to higher printing quality.

- Automatic Lap Adjustment Function

- The folder features an automatic lap adjustment function used to calculate the degree of lap difference and automatically adjust and maintain the correct lap value.

Operator Friendly Environment

Realizing ideal operating conditions through use of sophisticated press control functions

Press operation methods have been improved to assist in reducing the workload of the operator. All factors influencing control of the press were reviewed in detail. A number of developments are introduced, including enhanced master console control functions, noise reduction, and the new unit design and color scheme. Mitsubishi has effectively achieved a true ergonomically designed, operator-friendly press.

- Work Environment Considerations

- Work Environment Considerations In addition to reducing electrical power consumption, the DIAMONDSTAR also creates a more operator-friendly environment by shortening required makeready time, reducing operating noise level, and maximizing the advantages of the shaftless drive system. Soundproofing materials within the folder framework contributes to much quieter high-speed operations.

- Press Control Station: CCS-PC

- The ergonomically designed master console features a greater number of graphic color displays for easier operations.

The console includes multiple press presetting functions and enables centralized control of reel stands, printing units and folders via a touch-sensitive color monitor.

Standard specification

Slide horizontally to see the table.

| Maximum printing speed | 90,000 IPH |

|---|---|

| Cutoff | 533mm,546mm,560mm,578mm (21",21.5",22",22.75") |

| Web width | 1,220mm to 1,680mm (48" to 66") |

| Reel diameter | 1,270mm (50") |

| Maximum number of pages | 96 Pages in straight, 160 pages in collect |

| Inking system | Open fountain/Digital ink pump |

| Dampening system | Spray bar |

| Reel stand | Independent arm, 2-arm/3-arm |

| Folder | 2:5:5 Jaw, 2:3:3 Jaw, 3:2 Rotary |

| Drive system | Shaftless |

DIAMONDSPACE

The Well-Reputed 4×2 Press and Continuous Leader in Worldwide Newspaper Press Technology

Standard specification

Slide horizontally to see the table.

| Maximum printing speed | 75,000 IPH/70,000 IPH |

|---|---|

| Cutoff | 533mm,546mm,560mm,578mm (21",21.5",22",22.75") |

| Web width | 1,270mm to 1,680mm (50" to 66") |

| Reel diameter | 1,270mm (50") |

| Maximum number of pages | 96 Pages in straight, 160 pages in collect |

| Inking system | Open fountain/Digital ink pump |

| Dampening system | Spray bar |

| Reel stand | Independent arm, 2-arm/3-arm |

| Folder | 2:5:5 Jaw, 2:3:3 Jaw, 3:2 Rotary |

| Drive system | Shaftless |

DIAMONDSPIRIT

High speed 4×1 Press (Maximum Printing Speed: 80,000 IPH)

Mitsubishi has developed high speed 4×1 shaftless newspaper offset press. Narrow gap cylinders are employed for both plate and blanket cylinders to reduce vibrations. The use of double-diameter blanket cylinders stabilizes deflection of single-diameter plate cylinders and contributes to high-quality printing of 80,000 IPH. Moreover, the customer has the option of choosing either conventional blankets or metal-backed blankets.

Standard specification

Slide horizontally to see the table.

| Maximum printing speed | 80,000 IPH |

|---|---|

| Cutoff | 533mm,546mm,560mm,578mm (21",21.5",22",22.75") |

| Web width | 1,270mm to 1,680mm(50" to 66") |

| Reel diameter | 1,270mm(50") |

| Maximum number of pages | 96 Pages |

| Inking system | Open fountain/Digital ink pump |

| Dampening system | Spray bar |

| Reel stand | Independent arm,2-arm/3-arm |

| Folder | 2:5:5 Jaw, 2:3:3 Jaw, 3:2 Rotary |

| Drive system | Shaftless |

The DIAMONDSPIRIT is not available for sale in and delivery to the following countries: U.S.A., UK, Germany, France, Switzerland, Sweden, and Liechtenstein.