Shipbuilding Engineering:Hull Form Development

Shipbuilding Engineering:Hull Form Development

Distributors :

We provide energy efficient hull form to comply latest environmental regulations based on advanced CFD tools and vast tank test database.

Performance Estimation・CFD Analysis・Hull Form Optimazation

It is our design philosophy to carry out hull form optimization based on actual operational profile, so that it would obtain flexible performance on various speeds and drafts. Not only our hull form complies latest EEDI regulations, but also contributes to reduction of environmental burden through energy savings in actual daily operations.

- Vast model test database accumulated over 100 years of history

- Sea trial feedbacks from new-building ships

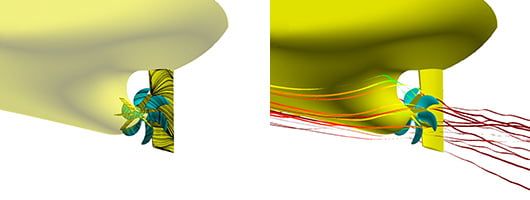

- Hull form optimization supported by advanced CFD analysis

- Simultaneous CFD analysis combined with propeller, rudder and energy saving device to seek the best combination

Energy Saving Devices

Mitsubishi Reaction Fin

- Energy Savings of 6 – 8%

- Suitable for blunt hull form such as bulkers and tankers

- Fitted over 140 ships

Mitsubishi Air Lubrication System (MALS)

- Air bubble carpet will reduce the viscosity resistance of flat bottom

- Performance confirmed of 5% with cruise ship, 12% with module carrier

- Suitable for shallow draft, blunt hull form

- Fitted on 21 ships