TECHNICAL REVIEW DIGEST

Back numbers (from 2019)

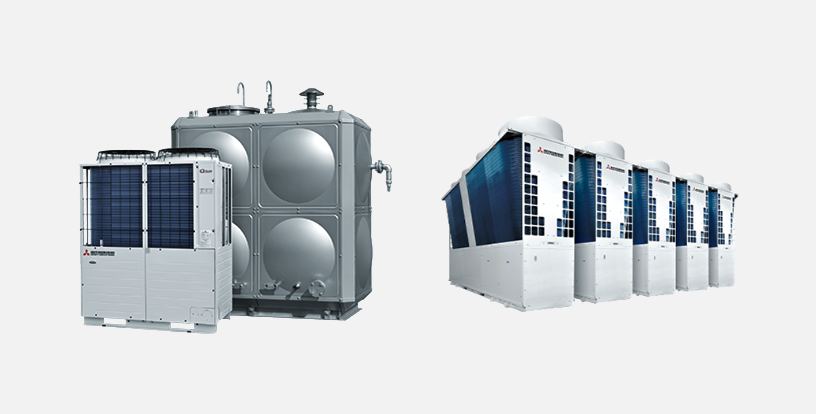

Aquifer Thermal Energy Storage System of Low GWP Turbo Heat Pump Utilizing Unused Energy

Centrifugal chiller

Groundwater, which lies in abundance beneath our feet, is retained in a geological formation called an aquifer made of materials such as sand and gravel. Compared with the outside air temperature, groundwater is warmer in the winter and cooler in the summer. Because of this difference in temperature, it is of high value as a heat/cold source, but this energy has been unused. In air conditioning systems known as aquifer thermal energy storage (ATES) systems, aquifers are used as if they were large heat/cold storage tanks. Using a centrifugal heat pump, waste heat produced during cooling operations and waste cold during heating operations are stored in aquifers. This enables the former to be effectively used for heating and the latter for cooling in different seasons. Mitsubishi Heavy Industries Thermal Systems, Ltd. developed a heating/cooling system that uses a high-efficiency centrifugal heat pump suitable for ATES systems and an energy management optimization control system.

Details of this article

- Vol. 58 No. 2 (2021) Logistics, Thermal & Drive Systems

Engine-driven Refrigeration Unit TU series using Low GWP Refrigerant

Truck refrigeration unit

Suppression of global warming is a global issue and countermeasures are being taken for products in various

fields. Transport refrigeration units installed in many trucks and trailers that support the controlled

temperature transportation infrastructure for perishable foodstuffs, pharmaceuticals and industrial raw

materials are also required to play their own roles, while reducing the impact of global warming at the same

time.

Mitsubishi Heavy Industries Thermal Systems, Ltd. promptly developed the TU series, engine-driven transport

refrigeration units (hereinafter referred to as the "developed product") that use a refrigerant with a low

global warming potential (GWP) in order to lead the contribution to the suppression of global warming in the

transport refrigeration unit industry. This report presents the developed product.

Details of this article

- Vol. 58 No. 2 (2021) Logistics, Thermal & Drive Systems

Low Vibration Electric Compressor for Air Conditioning System of Hybrid & Electric Vehicles

Automotive air-conditioners

Mitsubishi Heavy Industries Thermal Systems, Ltd. (MHITS) has been marketing electric compressors for air conditioning systems for hybrid and electric vehicles since 2007 and has achieved reduced size and weight, as well as high efficiency, through the introduction of its unique scroll technology, inverter control system and optimized internal structure. In order to secure a higher level of in-car quietness, MHITS has now developed a new electric compressor that reduces the vibration by about 25% compared with the current model while maintaining the same size and performance, by optimizing the balance through an update of the internal structure.

Details of this article

- Vol. 58 No. 2 (2021) Logistics, Thermal & Drive Systems

Sliding Surface Improvement Technology Using Low Friction Surface Treatment to Reduce Friction Loss and Improve Efficiency of Products

compressor for air-conditioners

Using ta-CNx coatings deposited by the IBA-FAD (Ion Beam Assisted Filtered Arc Deposition) method, we conducted friction tests. The test results showed that the friction coefficient in dry friction of refrigerant environment was about 0.02 and the friction coefficient in mixed environment of refrigerant and refrigerating oil was 0.03 or less. The ta-CNx coatings expressed low friction coefficients about one-third or less of the friction coefficients of current DLC coatings (Diamond Like Carbon Coatings), which are generally about 0.1. Compared with the DLC coatings of other companies (which have been used for automobile engines) and no coating, which exhibits friction coefficients of 0.1 to 0.15, the ta-CNx coatings we developed showed significantly lower friction coefficients. Furthermore, in the environment of engine oil, under the condition where an additive agent was additionally mixed with the oil, the ta-CNx coating showed a low friction coefficient of 0.04. We observed the sliding faces after friction tests and analyzed them with reflectance spectroscopy. As a result, we found that there was tribo-film formed on the friction surface and clarified the low friction mechanism of ta-CNx coatings. In addition, as one example, we applied the developed ta-CNx coatings to the sliding parts of a compressor of an air conditioner and confirmed that the efficiency was improved by about 1%.

Details of this article

- Vol. 58 No. 1 (2021) New Products & Technologies

Development of Numerical Simulation Method for Evaluation of Gas-Liquid Two-Phase Flow Distribution

Heat exchanger

Mitsubishi Heavy Industries Group provides heat exchangers used in chemical plants, boilers, air conditioners, etc. In heat exchangers, gas-liquid two-phase flow is distributed to multiple heat transfer tubes by a cone-type or header-type distributor. To predict the flow distribution characteristics, we need to consider not only the behavior of the gas-liquid two-phase flow in the distributor, but also the pressure drop in the heat transfer tubes on the downstream side. Therefore, we developed a flow distribution prediction method by coupling numerical analysis for the flow in a distributor and a one-dimensional model for the pressure drop in heat transfer tubes. The results obtained by the developed prediction method were compared with the experimental results, and it was verified that regardless of the presence or absence of phase change due to heat exchange in heat transfer tubes, the developed method could predict the liquid-phase distribution ratio with practical accuracy.

Details of this article

- Vol. 57 No. 1 (2020) New Products & Technologies

Development of Large Capacity Compound Type Centrifugal Chiller and Centrifugal Heat Pump Using R1234ze(E)

Centrifugal chiller

Conventionally, heat source equipment for low-temperature processes in the industrial field has used propane (R290) and ammonia (R717, NH3), but they place a heavy burden on customers for safe operation due to their flammability and toxicity. Therefore, alternative products with low environmental impact are being demanded. Currently, the move toward terminating the use of HFCs is being accelerated with the agreement of countries around the world, such as the adoption of the Kigali Amendment to the Montreal Protocol. In the air conditioning field, R1234ze(E), which has low toxicity and a GWP (Global Warming Potential) of 1 or less, has been used for centrifugal chillers used as heat source equipment for large-scale facilities. To expand the application range of low-GWP refrigerants in the industrial field, we have established a technology for the multi-stage compression refrigeration cycle using R1234ze(E) that enables the supply of -20°C or lower-temperature brine and 60°C hot water. This technology can also be used for heating tower applications.

Related products

- Centrifugal chiller, GART-ZE & ZEI series (Link to products site)

Uses low GWP refrigerant HFO-1234ze(E)

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Optimization of Process Cooling for Food Using Variable Speed Centrifugal Chiller Operating at Ultra-Low Load with Low-GWP Refrigerant

Centrifugal chiller

Along with the stricter regulations on refrigerants and the enforcement of the Law Concerning the Discharge and Control of Fluorocarbons for the purpose of preventing global warming, the need for low-GWP refrigerant (non-CFC) chillers has been increasing. On the other hand, in process cooling systems at food factories where chillers are used, excessive starts and stops of chillers sometimes occur because the chillers cannot follow the load variation in batch operations in which the load changes abruptly in a short time. Mitsubishi Heavy Industries Thermal Systems, Ltd.(MHI Thermal Systems) introduced a two-stage cooling system using temperature difference for which the variable speed centrifugal chiller operating at ultra-low load was adopted, an exhaust heat recovery (hot water supply) system and other technologies to promote the delivery of high-efficiency systems that allow stable continuous operation at varying loads.

Related products

- Centrifugal chillers (Link to products site)

Realizing major energy savings, cost reductions and cuts in CO2 emissions

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of HCCV2001M, the World's First Large-capacity Condensing Unit equipped with two CO2 Scroll and Rotary compressors

Freezer and refrigeration unit

To prevent global warming, refrigeration and air conditioning equipment is required to replace current refrigerants with those with low global warming potential (GWP) to achieve a reduction in GWP. Mitsubishi Heavy Industries Thermal Systems Ltd. has developed the HCCV2001M, a large-capacity 20-horsepower condensing unit following the 10-horsepower HCCV1001, both of which adopt natural refrigerant CO2with a GWP of 1 as an alternative to fluorocarbon refrigerants R404A (GWP3920) and R410A (GWP2090), which are the mainstream refrigerants used in commercial condensing units. This larger capacity was established by using two Scroll and Rotary compressors, which expanded the capacity range while accommodating the components in a cabinet the same size as that of the HCCV1001. As a result, the installation flexibility was ensured. This paper describes the technological issues and applied technologies of this product.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of Demonstration Unit of Residential Air Conditioner Adopting Low-GWP Refrigerant to Replace R32

Residential air-conditioners

Wide-ranging regulations have been introduced to deal with global warming, and various measures have been

implemented accordingly. Under such circumstances, air conditioning and refrigeration systems are required to

not only have energy-saving features, but also start using alternative refrigerants with less environmental

impact.

Adopting R454C refrigerant, which has an extremely low global warming potential (GWP), Mitsubishi Heavy

Industries Thermal Systems Ltd. has developed a demonstration unit of a residential air conditioner with

enhanced environmental properties. The global warming impact of this demonstration unit represents a reduction

of more than 90% from that of our earlier models.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of Evolutionary Three-Dimensional Scroll Compressor Realizes Energy Saving in Air Conditioning and Refrigeration Equipment

Compressor

Mitsubishi Heavy Industries Thermal Systems Ltd. proposed a three-dimensional scroll (hereinafter referred to as 3D scroll as a proprietary compression mechanism in 2004, and has been producing and selling air conditioning and refrigeration equipment featuring a 3D scroll compressor since 2007. The 3D scroll changes the height of the compression chamber during compression by providing steps at the wrap tip and bottom of the scroll to enable compression in the axial direction. For this reason, a compact and large-capacity compression mechanism can be configured in contrast to general two-dimensional (hereinafter referred to as 2D) scrolls. However, the leakage loss from the minute clearance in the step part, which is unique to a 3D scroll, was an issue for further improvement in efficiency. This time, as a solution to this issue, we have developed an evolutionary 3D scroll "e-3D scroll(Note)" compressor, which achieves a reduction in the leakage loss and improvement in efficiency, while maintaining the 3D scroll's advantages of small size and large capacity, for heat pump module chillers and VRF (Variable Refrigerant Flow) systems.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of Japan’s First Air-source Circulation Type Heat Pump Using R454C

Heat pump

Mitsubishi Heavy Industries Thermal Systems, Ltd. worked on product development for an air-source circulation type heat pump using environmentally-friendly low-GWP refrigerant that contributes to energy saving in the industrial field, and successfully launched a product that realizes the hot water temperature at outlet of 75°C at an outside air temperature as low as -20°C, while featuring a high efficiency of the rated COP of 3.3. We also actually introduced this product as a heating source of hot water for washing production equipment and confirmed its economic efficiency and environmental effects. Through the introduction of a hybrid system of this product and an existing gas-fired steam heater, in which this product covers the base heat load, it is expected that the running cost and CO2 emissions will be reduced by about 50%, leading to a substantial reduction in environmental load.

Related products

- Heat pump cold and hot water products / Air-cooled heat pump chillers / Hot wind generator (Link to products site)

Earth, nature, heat pumps. Making hot water from air-source heat

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Efforts to Acquire Automotive SPICE Certification in Automotive Software Development

Automotive air-conditioners

Having been formulated as the industry’s standard process model/assessment model, Automotive SPICE provides a common framework for in-vehicle device software development processes. With the promotion of Automotive SPICE-based process improvement as part of software quality improvement activities, Mitsubishi Heavy Industries Thermal Systems, Ltd. (MHI Thermal Systems) acquired Level 3 certification for the development capability of its electric compressors for automotive air conditioners. This report describes the various activities and strategies we undertook for the acquisition of the certification.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of Heat Pump System for xEVs

Automotive air-conditioners

In recent years, xEVs (including BEVs, HEVs, PHEVs, and FCEVs) have rapidly spread across the globe in an effort to meet stricter environmental regulations. Under such circumstances, it is required to reduce the amount of power used for air conditioning, which directly affects their driving range. For the heat pump systems of xEVs that can reduce the power consumption of air conditioning in winter, we made computational models of the air conditioning cycle and its control system, and through simulation studied the control of heat pump systems to achieve both power saving and thermal comfort.Subsequently, we also confirmed that both high efficiency and thermal comfort can be achieved by controlling the components of the heat pump system properly with vehicle test.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

"Hyper Inverter" Compact and Lightweight Packaged Air Conditioner

Packaged air-conditioners

Recently, the reduction of carbon dioxide emissions has been required to prevent global warming, and in the

case of packaged air conditioners, it is necessary to convert to a refrigerant with a low global warming

coefficient and improve efficiency to reduce power consumption. On the other hand, there is strong request for

downsizing and weight reduction of the outdoor unit due to restrictions of installation locations and ease of

transportation and carry-in, which must be balanced with improvements in efficiency.

Mitsubishi Heavy Industries Thermal Systems, Ltd. has developed the Hyper Inverter series of packaged air

conditioners, which are compact, lightweight and highly efficient. This paper introduces the characteristics and

specifications of the outdoor units.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

FDTC series 4-way Ceiling Cassette Compact Air-Conditioner featuring European Design

Commercial air-conditioners

In the grid system ceilings common in European offices, lighting, ventilation holes, etc., are arranged to match the grid of the system ceiling, and air conditioners are also installed. For compact cassette type indoor units often used in office applications, flat design panels that fit the entire ceiling design are preferred. To meet these market needs, we have developed a compact cassette type indoor unit, the FDTC series, which fits system ceilings.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Remote Monitoring and Energy Saving of Air Conditioners M-ACCESS Air Conditioner IoT Remote Monitoring System

VRF

Recently, there has been a growing need to connect home appliances to the internet, and there is a similar trend in commercial air conditioners installed in office buildings. If there were a system that can monitor and control the operating status of air conditioners at remote locations, it would be possible to pre-cool and pre-warm by the air conditioners when users return from outside, also making it possible to turn off air conditioners remotely. Furthermore, the power consumption of air conditioners is said to account for 20% to 40% of the annual power consumption of buildings, and by optimally controlling air conditioners, it is possible to reduce this amount. M-ACCESS is a system that automatically controls the power consumption of air conditioners using cloud-based servers, and this system realizes energy saving without spontaneous operation by users. This system also contributes to the control of global warming through development on a global scale.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Generator-driven Type Transportation Refrigeration Heat-Pump Unit for Trailers

Truck refrigeration unit

Along with global initiatives to reduce environmental impact, the implementation of such measures is also being promoted in the logistics industry. In terms of transportation refrigeration units, there is a strong need to reduce CO2emissions through efforts such as improved energy-saving features and lowering the noise level during operation/transport in urban areas or at night. In response to such demands for lower environmental impact, Mitsubishi Heavy Industries Thermal Systems, Ltd. has developed the TFV150GA transportation refrigeration unit for trailers with a generator-driven heat pump, to make both silent operation and energy conservation simultaneously possible.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

TE Series Small Electrically-driven Refrigeration Units with Generator for Delivery Trucks

Truck refrigeration unit

The rise of E-commerce industry and home delivery services have rapidly increased the amount of cargo handled

by logistic industry worldwide. This development poses both a social as well as environmental challenge to

reduce the burden on truck drivers as well impact on environment. In particular, for delivery trucks that

require refrigerated transportation, there is growing demand for improved temperature maintenance, operability

and lower running costs through the adoption of electric refrigeration units.

Mitsubishi Heavy Industries Thermal Systems, Ltd, has developed all-electric ‘TE series’ refrigeration unit

compatible with diesel trucks, which make up the majority of transportation vehicles to meet the aforementioned

market demand with a dedicated alternator and battery. This report introduces the developed refrigeration unit

TE series.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Large Capacity Electric Compressor for Air Conditioning System of Hybrid Electric Vehicles

Automotive air-conditioners

Mitsubishi Heavy Industries Thermal Systems, Ltd. has marketed electric compressors for air conditioning systems of hybrid electric vehicles since 2007, and achieved the industry's top class of small, light, and more efficient compressors featuring its unique scroll technology, inverter control system and optimized internal structure. We have developed a new series of large-capacity electric compressors to meet the needs of electric vehicles such as the promotion of battery cooling during rapid charging and the expansion of heating capacity for application to heat pumps. The developed product has achieved a significant increase in cooling capacity while minimizing the increase in body size by optimizing the internal specifications in comparison with the current product.

Details of this article

- Vol. 56 No. 4 (2019) Air-Conditioning & Refrigeration

Development of Numerical Evaluation Method for Unsteady or Phase-changing Gas-liquid Two-phase Flow

Heat exchanger

Mitsubishi Heavy Industries Group provides plant piping and heat exchangers. When designing these products, the so-called gas-liquid two-phase flow phenomenon must be considered. Gas-liquid two-phase flow involves physical phenomena such as phase change and gas-liquid interfacial drag, which do not occur in single-phase flow. It is very difficult to predict or evaluate gas-liquid two-phase flow compared to single-phase flow. We have developed a two-phase flow analysis method based on the two-fluid model and conducted performance and design index evaluations for related products. This article introduces the overview of the technology.

Details of this article

- Vol. 56 No. 1 (2019) New Products & Technologies

TECHNOLOGY

- TECHNICAL REVIEW DIGEST R&D, academic papers, etc., associated with Mitsubishi Heavy Industries Thermal Systems, published in Mitsubishi Heavy Industries' Technical Review Digest. Check out the list of R&D papers from the past to the present.

- AWARDS Introduction to the awards won so far.

- DEVELOPMENTAL PROCESS AND SYSTEMIntroduction to the developmental process and system needed to realize cutting-edge thermal solutions.

- ON-SITE

DEVELOPMENT Check out articles on interviews of on-site developers.

Our advanced technologies are propped up by the convictions and passion of staff.