TECHNICAL REVIEW DIGEST

Latest R&D and papers

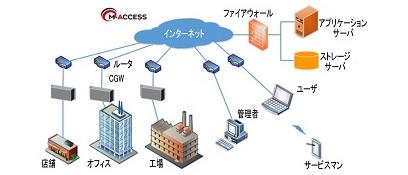

Customer Portal Enhances Customer Experience Value in MHI Centrifugal Chillers

Centrifugal chillers

Centrifugal chillers are mainly used as heat sources for factory air conditioning and district heating and cooling

system. As with residential air conditioners, the electricity costs account for a large portion of their operating

costs, so energy saving is important. However, it is not easy for customers to correctly monitor the equipment

status and improve energy efficiency on their own. Furthermore, As the machine ages, it is more difficult to keep

track of maintenance records, which makes it even harder to perform effective maintenance. To solve these problems,

Mitsubishi Heavy Industries Thermal Systems, Ltd. (MTH) has launched a portal site which helps our customer s to

easily access to machine specifications, recommended maintenance plans and records, as well as real time chiller

operation status when necessary.

In addition, by integrating the portal site with the introduction of IoT to centrifugal chillers, MTH have

visualized energy efficiency and loss, and have started to provide solutions for realizing data-based energy saving.

Details of this article

- Vol. 59 No. 3 (2022) Digital Innovation

Development of Inverter Control for Room Air Conditioners for Dealing with Voltage Distortions in Low Quality Power Supply Environments

Inverters

Inverters used for room air conditioners, which are household-use air conditioners, cause the outflow of harmonic current with a frequency other than the power supply frequency to the input current. This harmonic current is regulated and measures to meet the regulations are required and we have responded to the regulatory. On the other hand, if the waveform of the power supply voltage is distorted, the input current is distorted and the current increases and there are problems such as the deterioration of the efficiency and fuses blowout due to overcurrent in some cases. Therefore, Mitsubishi Heavy Industries Thermal Systems, Ltd. calculated the distortion factor of the input current and conducted control so as to reduce it. As a result, it was confirmed that the total distortion factor could be suppressed to 1/5 to 1/2 and reported.

Details of this article

- Vol. 59 No. 1 (2022) New Products & Technologies

Renovation Controller to Realize Long-Life of Chiller

Centrifugal chillers

The controllers of centrifugal chillers manufactured by Mitsubishi Heavy Industries Thermal Systems, Ltd. (MTH) are proprietary products of MTH. However, it was impossible to replace existing controllers with the latest ones due to the significant difference between old and new controllers and the difficulty in ensuring compatibility. Nevertheless, many centrifugal chillers that were released more than 10 years ago and are equipped with old controllers are still in service and they will continue to be used for a long time in the future. In order to reassure our customers that they can operate MTH centrifugal chillers for a long time without issue, we have developed a renovation controller with the latest features compatible with older controllers.

Details of this article

- Vol. 59 No. 1 (2022) New Products & Technologies

Development of Humidity Control Outdoor Air Processing Air Handling System (Direct X Comfort) Achieving Both Energy Saving and Comfort

Air handling units

Today, it is recommended to raise the cooling temperature setting as a method of saving energy in building air conditioning. However, many air conditioners depend exclusively on dry-bulb temperature control and during the rainy season, their dehumidifying capacity for latent heat may be insufficient, resulting in discomfort. One of the causes of the latent heat load, which is a factor in this discomfort, is often the intake of outdoor air by ventilation. This time, we have commercialized a humidity control outdoor air processing direct expansion air handling system (Direct X Comfort), which has a cooling dehumidification function that controls the dew point temperature and a reheating function that utilizes waste heat, in addition to the functions of conventional outdoor air processing direct expansion air handling systems. By using waste heat from the heat pump as the heat source for reheating, this system has achieved a 60% reduction in power consumption compared to the conventional desiccant system that uses an electric heater as the heat source for regeneration.

Details of this article

- Vol. 58 No. 2 (2021) Logistics, Thermal & Drive Systems

Back numbers (from 2019)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

TECHNOLOGY

- TECHNICAL REVIEW DIGEST R&D, academic papers, etc., associated with Mitsubishi Heavy Industries Thermal Systems, published in Mitsubishi Heavy Industries' Technical Review Digest. Check out the list of R&D papers from the past to the present.

- AWARDS Introduction to the awards won so far.

- DEVELOPMENTAL PROCESS AND SYSTEMIntroduction to the developmental process and system needed to realize cutting-edge thermal solutions.

- ON-SITE

DEVELOPMENT Check out articles on interviews of on-site developers.

Our advanced technologies are propped up by the convictions and passion of staff.